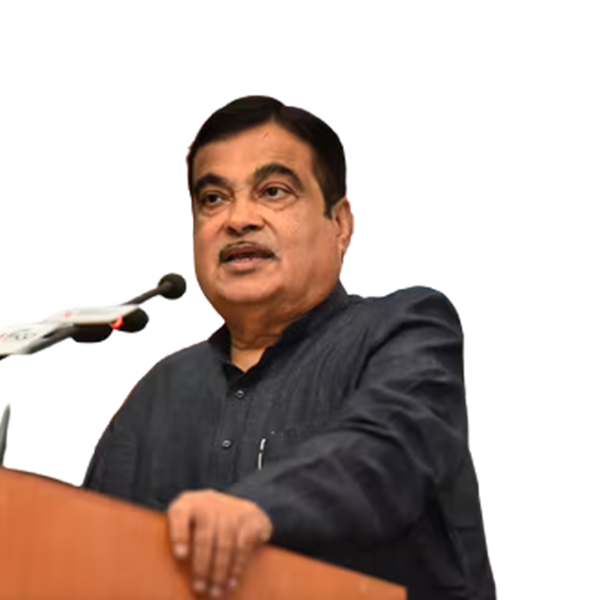

India’s Minister of Road Transport and Highways,Shri Nitin Gadkari, has not only endorsed but actively encouraged the use of GFRP rebars in lieu of traditional steel. This visionary stance is a testament to the transformative potential of GFRP rebars in the Indian construction landscape. Gadkari Ji recognizes the multifaceted benefits of GFRP rebars, from cost-efficiency to sustainability, and their ability to revolutionise the way infrastructure is built and maintained.

GFRP REBAR Manufacturer in Gujarat. Bharat Infrastructure is one of the leading manufacturer, supplier and exporter in Gujarat, India. Contact us and get the best products. Contact us and get the best products.

Bridges, highways, tunnels, and retaining walls, especially in corrosive or marine environments.

Jetties, wharves, seawalls, and other structures exposed to saltwater and harsh weather conditions.

Underground tanks, water treatment plants, and swimming pools, due to its impermeability and resistance to corrosion.

Chemical processing plants, factories, and other facilities where resistance to chemicals and corrosion is essential.

Foundations, slabs, and walls, especially in areas with high moisture or chemical exposure.

GFRP rebar's lightweight nature and corrosion resistance make it ideal for precast concrete components.

GFRP's high tensile strength and flexibility make it suitable for strengthening existing structures

GFRP rebar is also used in underground structures, transportation infrastructure (roads, sidewalks, and parking garages), and areas with electromagnetic interference concerns (e.g., MRI rooms, control towers)

A water containing structure in any tank like architectural feature constructed using RCC to hold water/ chemicals. RCC tanks (swimming pools, water channels, drain channels, ETP, Stp etc experience severe corrosion problems resulting from direct contact with moisture and the application of special treatment method of chemicals. Governments of the world spend hundreds of millions of dollars annually to replace and repair such corroded RCC tanks. GFRP REBAR is water resistant and thus does not corrode, which provide long life to your structures.

See Details

Road Infrastructure include roads, bridges, flyovers, culverts, elevated roads, tunnels, railway over bridge, under bridges, foot over bridges, footpaths, cycle tracks, concrete pavement, sidewalks. Due to malpractices in material and construction processes, millions of dollars is spend on reconstructing damaged roads, which also delays the construction period.

While GFRP Rebar enables the faster construction process, which is anti corrosive, has superior tensile strength, and has higher mechanical performance rather than traditionally used reinforced bars.

Precast concrete is reinforced concrete that is cast away from the building site, and assembled on site. On its own it concrete has good compressive strength, but lacks tension and shear strength and can be subject to cracking when bearing loads for long periods. While GFRP Rebar offers high tension and shear strength to make for what concrete lacks. Traditionally used reinforced bars behave similarly to concrete in changing environment, which means they will shrink and expand with concrete resulting in cracking.

See Details

In construction grade slab is a relatively flat concrete structure built on the top of the soil at ground level. This simple slab design differs from the reinforced slab technique used for elevated concrete floors and does not require support from underground footers or foundation walls. To ensure the grade slab will offer the necessary strength and stability, installers must choose concrete mixtures and reinforcements with care. GFRP Rebar, here thus is a obvious choice.

See Details.jpg)

Port facilities are mostly built using reinforced concrete structures, however, since all these structures are located in or near salt water unavoidable corrosion of the steel used in the construction will always be a problem. GFRP rebar is especially well suited for the construction of port and offshore structures. When choosing GFRP as the material for the reinforcement the problem disappears. GFRP’s resistance to corrosion allows you to extend the lifespan of the structures and significantly save on costly future repairs. Pontoons made with GFRP last longer, withstand higher loads and does not require special care. The low weight of the GFRP increases buoyancy by decreasing the weight of the overall structure.

See Details.jpg)

Considering that GFRP rebar does not corrode or deteriorate due to salt makes it the optimum material to use for the construction of housing in coastal and marine areas and in areas where the ground is salty or where the sand used for the actual construction is contaminated with salt.

See Details

The possibilities for unwanted deterioration of bridge decks is a key issue in the field of bridge construction. Bridge decks are subject to heavy wear and tear due impacts of weather and climate, heavy loads as well as increased traffic. The main problem is caused when cracks occur in the surface and the reinforcement is starting to corrode. By replacing steel rebar with GFRP rebar the corrosion is prevented. The GFRP rebar has repeatedly been used very successfully and is a well proven material used for the reinforcement of concrete decks and other bridge structures. The use of a composite reinforcement for reinforcement of bridge decks, extends the life of the deck and allows you to save a lot of money.

See Details.jpg)

The inability of GFRP rebar to conduct electricity makes it the ideal material to use as reinforcement in electrical poles and for construction of power plants and other buildings used for housing high and low voltage electric appliances.

See Details